Most Popular Products

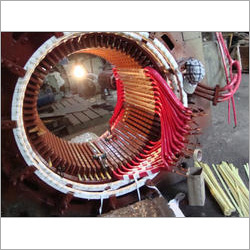

Motor Rewinding

Price 14700 INR/ Unit

MOQ : 1 , , Unit

Motor Rewinding Specification

- Service Type

- Motor Rewinding

- Material

- Copper Wire

- Voltage Range Supported

- 110V - 440V

- Insulation Class

- Class B / Class F

- Core Testing

- Done with Megger and Hi-pot Testers

- Phase

- Single Phase / Three Phase

- Usage/Application

- Industrial

- Capacity

- Up to 200 HP

- Frequency

- 50 Hz / 60 Hz

- Service Mode

- Offline

- Rewinding Timeframe

- within 24-48 hours

- Motor Type Supported

- AC Motor, DC Motor, Submersible Motor, Induction Motor

- Quality Assurance

- Fully Tested Before Delivery

- Winding Wire Material

- Super Enamelled Copper Wire

- Motor Cooling Type

- Air Cooled / Water Cooled

- Service Location

- On-Site / At Workshop

Motor Rewinding Trade Information

- Minimum Order Quantity

- 1 , , Unit

- Payment Terms

- Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Supply Ability

- 1 , , Unit Per Day

- Delivery Time

- 2 Days

- Main Export Market(s)

- Western Europe, Australia, South America, Eastern Europe, Middle East, Central America, Asia, North America, Africa

- Main Domestic Market

- All India

About Motor Rewinding

Ending Soon: Take advantage of our illustrious Motor Rewinding service, perfect for AC, DC, Submersible, and Induction Motors. Harness the peerless performance of super enamelled copper winding wire, supporting voltages from 110V to 440V and capacities up to a sensational 200 HP. Order and redeem our service for rapid resultsrewinding completed within 2448 hours. Rigorously tested with Megger and Hi-pot instruments and available on-site or at our workshop, each motor is guaranteed peerless quality and reliability. Fully compliant with insulation classes B and F, this is Indias most renowned industrial solution.

Why Choose Our Motor Rewinding Service?

Experience a competitive edge with our state-of-the-art rewinding equipment and materials. Each machine features advanced insulation, precision testing, and robust copper wiring, supporting both single and three-phase motors. This service is ideal for industries seeking reliable, long-lasting performance from air or water-cooled motors, no matter the application. With rapid turnaround and certified safety assurance, your equipment receives peerless care for sustained productivity.

Packaging, Samples, and Supply Capabilities

We offer tailored packaging solutions ensuring goods transport securely to your location. Connect for a quotationwhether a small sample or a large industrial order, our supply ability efficiently meets demand. Nominal sample charges apply, and every product is shipped with meticulous packaging for transit protection. Guaranteeing fast service, we ensure your rewound motors arrive dependable and ready for immediate use.

Why Choose Our Motor Rewinding Service?

Experience a competitive edge with our state-of-the-art rewinding equipment and materials. Each machine features advanced insulation, precision testing, and robust copper wiring, supporting both single and three-phase motors. This service is ideal for industries seeking reliable, long-lasting performance from air or water-cooled motors, no matter the application. With rapid turnaround and certified safety assurance, your equipment receives peerless care for sustained productivity.

Packaging, Samples, and Supply Capabilities

We offer tailored packaging solutions ensuring goods transport securely to your location. Connect for a quotationwhether a small sample or a large industrial order, our supply ability efficiently meets demand. Nominal sample charges apply, and every product is shipped with meticulous packaging for transit protection. Guaranteeing fast service, we ensure your rewound motors arrive dependable and ready for immediate use.

FAQs of Motor Rewinding:

Q: How long does the motor rewinding process take?

A: Our motor rewinding process typically takes between 24 to 48 hours, ensuring prompt service so your industrial operations can resume with minimal downtime.Q: What types of motors can be serviced through your rewinding offering?

A: We cater to a wide range of motors including AC, DC, submersible, and induction motors with capacities up to 200 HP. Single-phase and three-phase motors are both supported.Q: Where is the rewinding service performed?

A: We provide flexibility by offering our rewinding service both on-site at your facility and at our professionally equipped workshop, based on your operational needs.Q: What is the quality assurance process for rewound motors?

A: All motors undergo comprehensive core testing using Megger and Hi-pot testers to ensure insulation integrity and reliability. Each unit is fully tested before being delivered.Q: How is the rewound motor packaged and delivered?

A: Rewound motors are packaged with care to prevent transit damage, and reliable goods transport arrangements are made to deliver the motor securely to your specified location.Q: What are the benefits of using super enamelled copper wire for rewinding?

A: Super enamelled copper wire provides superior conductivity, heat resistance, and durability, resulting in enhanced efficiency and prolonged motor life even under demanding industrial conditions.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in CNC Machine Repair and Servicing Category

|

EPROMSIS TECHNOLOGIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry