Most Popular Products

WA 320W Water Jet Cutting System

Price 35000.0 INR/ Piece

MOQ : 1 Piece

WA 320W Water Jet Cutting System Specification

- Safety Features

- Emergency Stop, Splash Guard, Warning Indicators

- Maximum Traverse Speed

- 12000 mm/min

- Noise Level

- <75 dB

- Pump Type

- Direct Drive / Intensifier Pump

- Service Support

- On-site / Remote

- Weight

- ~3200 kg

- Operating Temperature Range

- 5°C - 45°C

- Nozzle Diameter

- 0.15 - 0.33 mm

- CNC Control System Brand

- Imported / Local (Optional)

- Precision Repositioning

- 0.05 mm

- Dimension (L x W x H)

- 3200 mm x 2200 mm x 1800 mm

WA 320W Water Jet Cutting System Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash Advance (CA)

- Supply Ability

- 10 Pieces Per Day

- Delivery Time

- Days

- Sample Available

- No

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- You will receive the product with company's original packaging.

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

- Certifications

- YES

About WA 320W Water Jet Cutting System

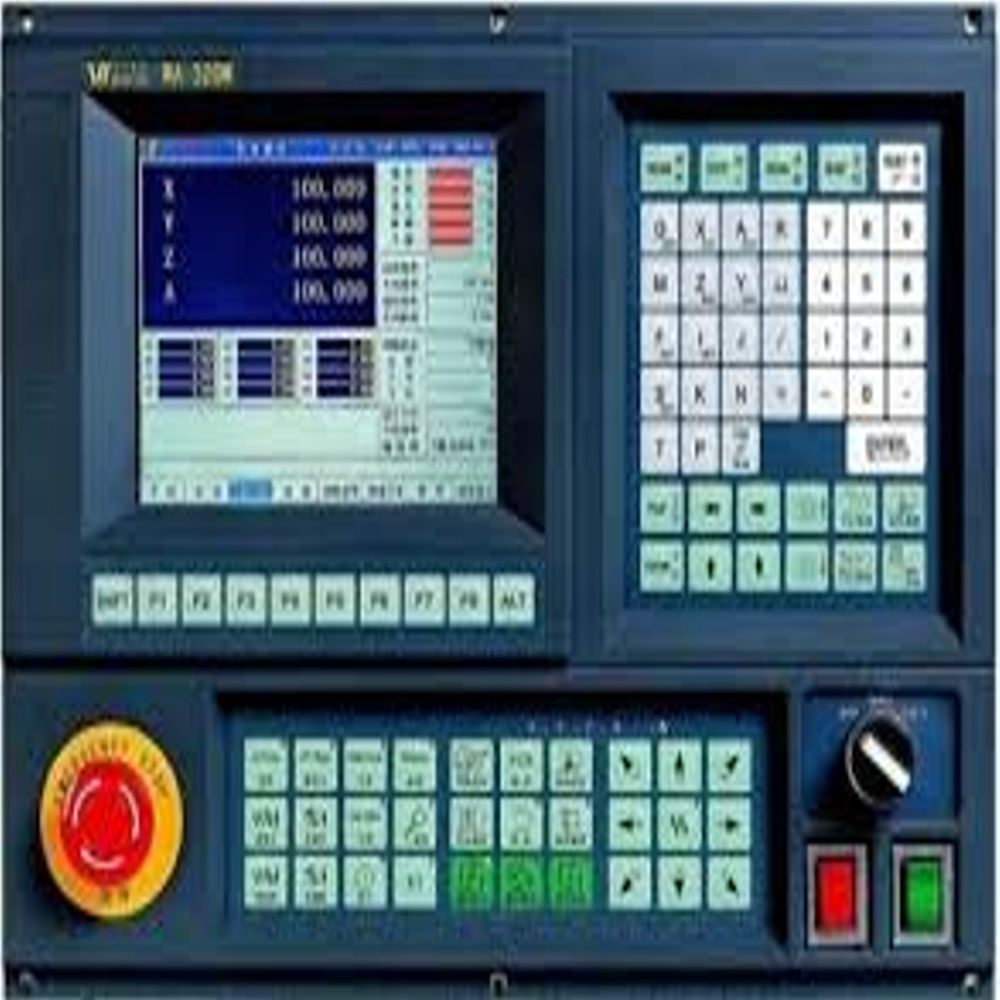

WA 320W Water Jet Cutting Systemis the new generation special control system supplied by our company based on the area of shooting stream of water control.The system aim at the characteristic of shooting stream of water incise,set many functions of special control,improve flexible and simplify of control.The software function of control is perfect which more apply for shooting stream of water control.WA-320W adopts the color display, Interface design is more abundant and humanized. Keyboard adopts project plastic with press model,handsome sculpt. The control structure adopts two CPU. The combination of 32 bits and 16 bits CPU have powerful procee performance. The convenient U disk interface can realize the mutual storing between the U disk and the system, and the on-site upgrading function for the system.Washing system up to more upper step with high dependability.

The system can control digital AC servo driver and the three phase micro-step driver; the electronic gear function of the system enables the system to be directly connected with any thread pitch screw rod; the pitch compensation function makes the precision test to the machine tools much more simplified, and improve machine tool synthesis precision.

Advanced CNC Control System Options

Tailor the systems performance with a choice between imported and locally sourced CNC control systems. This flexibility allows users to balance quality with budget considerations and ensures easy integration into various manufacturing setups. The controls facilitate user-friendly programming for custom cut paths, making operation efficient and precise.

Exceptional Safety and Support Features

Built with emergency stop functionality, splash guards, and safety indicators, the WA 320W prioritizes operator well-being. Comprehensive service support is available both on-site and remotely, maximizing uptime and addressing technical issues swiftly. These features safeguard production continuity and protect personnel.

FAQs of WA 320W Water Jet Cutting System:

Q: How does the WA 320W Water Jet Cutting System achieve precision in cutting operations?

A: The system utilizes a fine adjustable nozzle and highly accurate CNC control to reposition the cutting beam with a precision of 0.05 mm. Together, these technologies enable consistent and intricate cuts required for complex manufacturing tasks.Q: What pump types are available with the WA 320W, and which applications are they best suited for?

A: Customers can select either a direct drive or an intensifier pump. Direct drive pumps offer energy efficiency for lighter tasks, while intensifier pumps deliver higher pressures needed for cutting tougher or thicker materials.Q: When should maintenance or service be scheduled for the WA 320W?

A: Routine maintenance should align with manufacturer guidelines and workload intensity. Preventive servicing is recommended after a set number of operating hours or if the system exhibits a drop in cutting performance. Expert support is available on-site or remotely.Q: Where is the WA 320W Water Jet Cutting System manufactured and supported?

A: The machine is manufactured in India. Service support, including training, troubleshooting, and maintenance, is provided both on-site at your facility and remotely through digital channels for prompt assistance.Q: What are the main safety features of the WA 320W, and how do they protect operators?

A: The WA 320W integrates emergency stop buttons, splash guards, and warning indicators. These safeguards help prevent accidents, minimize exposure to water jets, and alert operators to potential system irregularities.Q: How can users benefit from choosing between imported and local CNC control systems?

A: Users may opt for an imported CNC controller for advanced functions and reliability, or a local controller for budget alignment and easier maintenance. This flexibility ensures optimal performance tailored to specific needs.Q: What materials can be processed using the WA 320W Water Jet Cutting System, and what is the typical usage process?

A: The system can cut a variety of metals, composites, glass, stone, and plastics. Users select nozzle size, set cut paths via the CNC system, and operate within recommended temperature and noise limits to achieve safe, efficient, and high-quality results.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in HMI Controller Repair and Service Category

|

EPROMSIS TECHNOLOGIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry